Graphene/Ni(111) Interface Optimization.¶

Introduction.¶

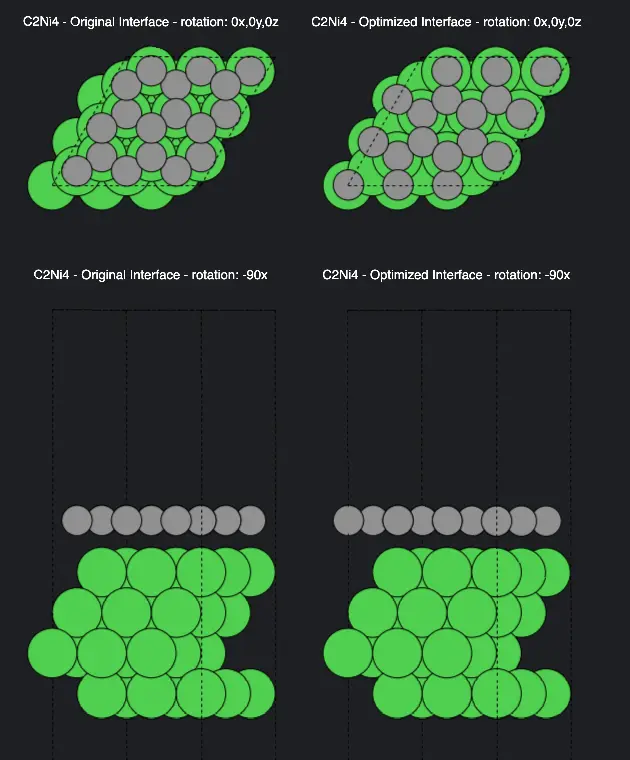

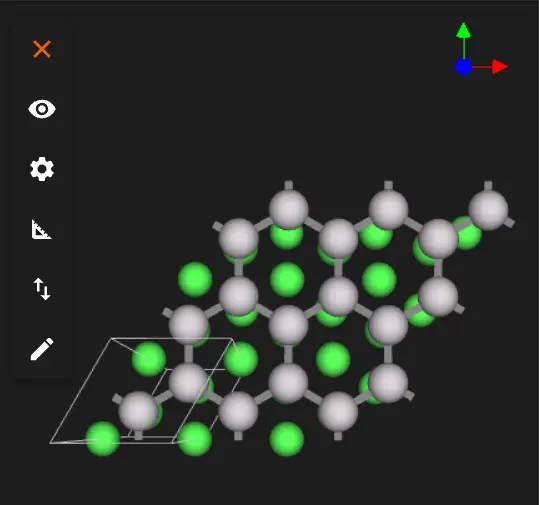

This tutorial demonstrates how to create and optimize a Graphene/Ni(111) interface structure following the experimental observations presented in the literature. We will focus on finding the most energetically favorable position of graphene on the Ni(111) surface.

Manuscript

Arjun Dahal, Matthias Batzill "Graphene–nickel interfaces: a review" Nanoscale, 6(5), 2548. (2014) DOI: 10.1039/c3nr05279f. 123

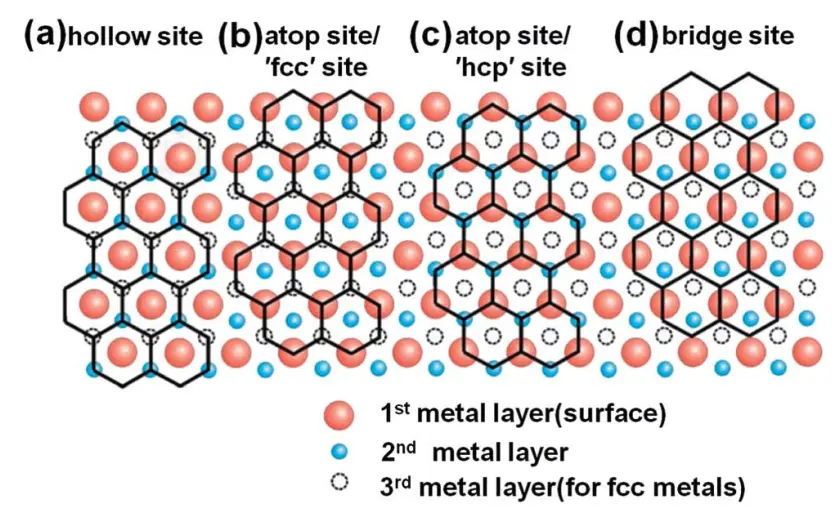

We will recreate the interface structure and optimize the film position to match the experimental findings shown in the figure below:

1. Create Interface Structure.¶

1.1. Load Base Materials.¶

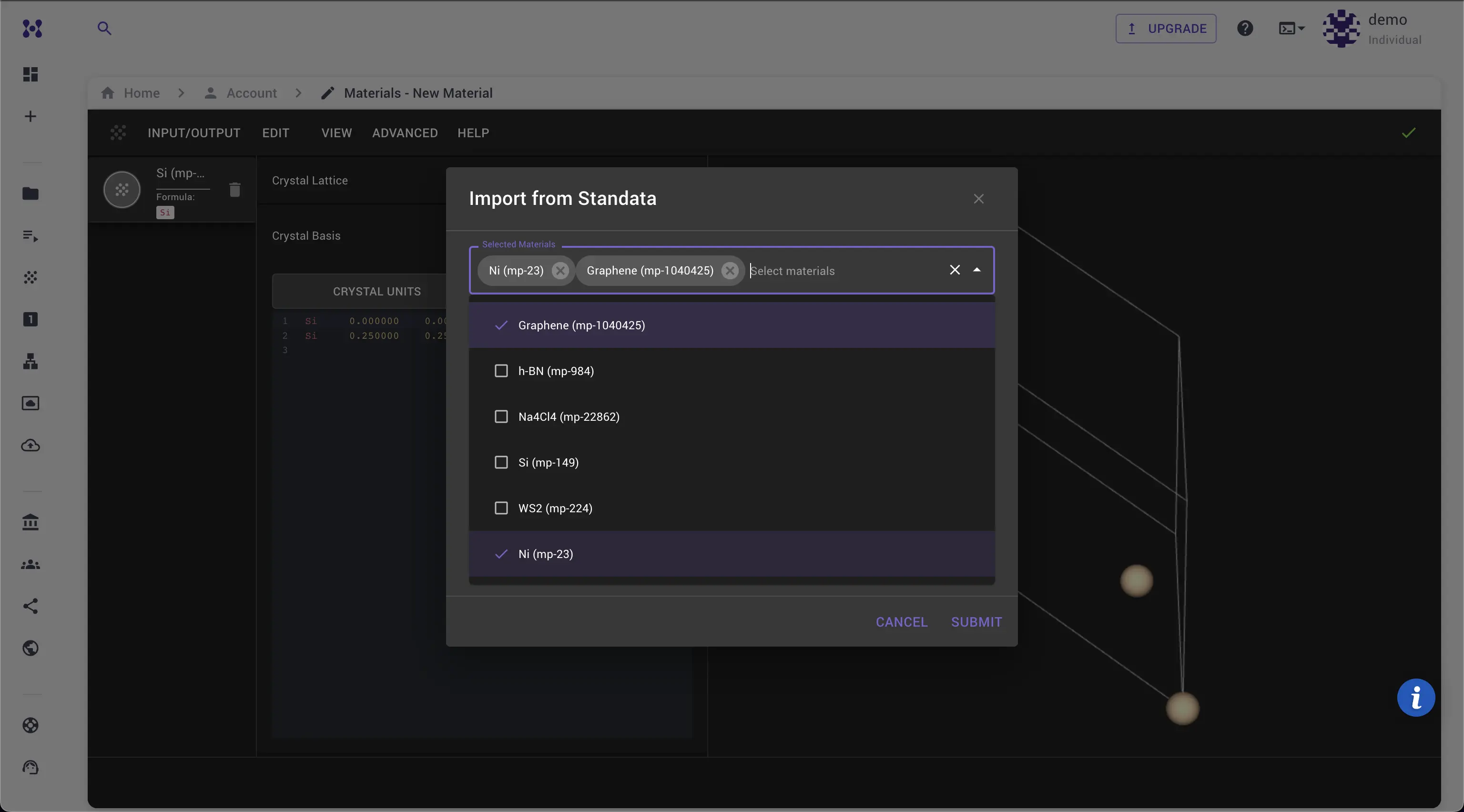

Navigate to Materials Designer and import both graphene and nickel materials from the Standata.

1.2. Launch JupyterLite Session.¶

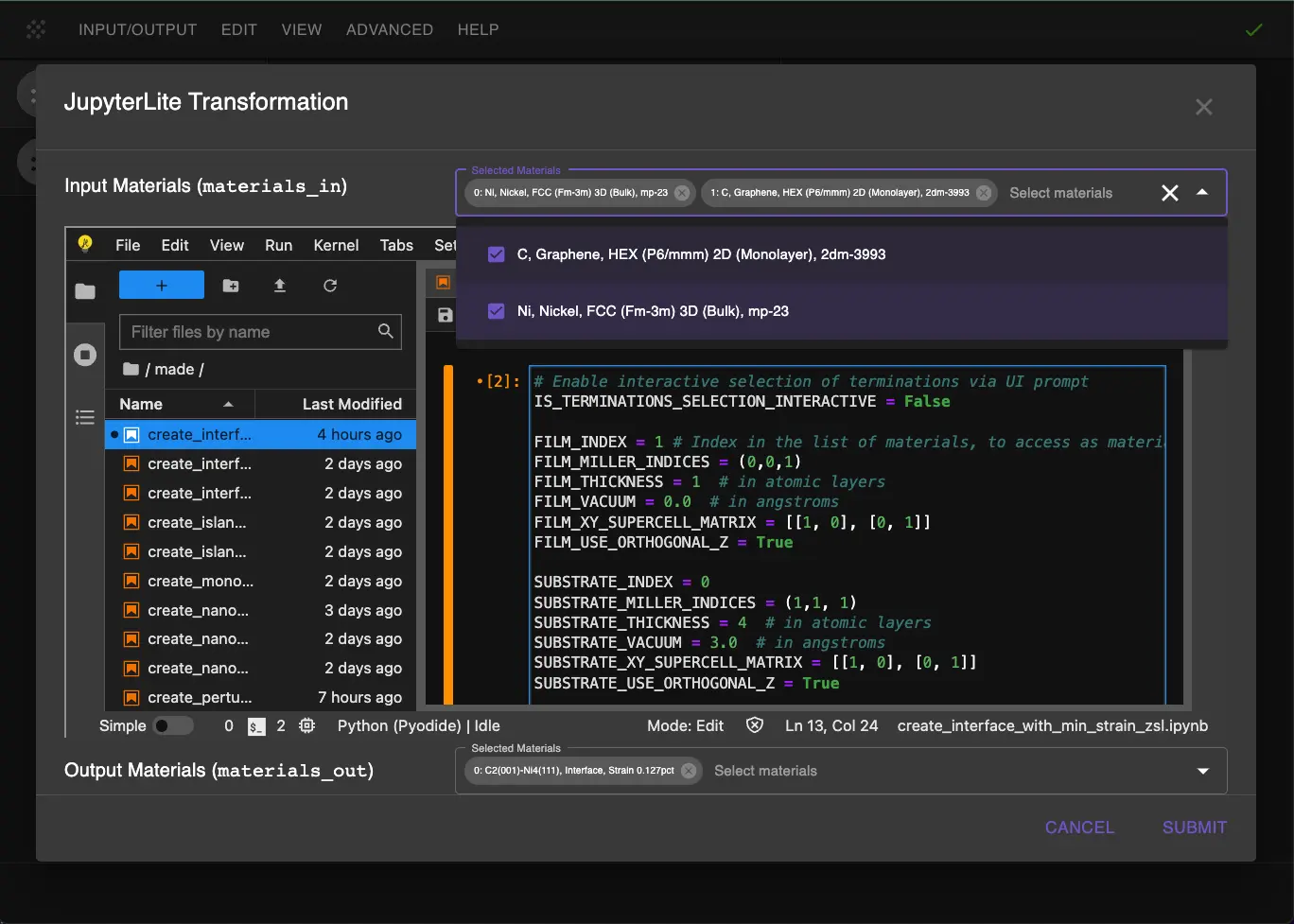

Select the "Advanced > JupyterLite Transformation" menu item to launch the JupyterLite environment.

1.3. Open create_interface_with_min_strain_zsl.ipynb notebook.¶

Find and open the create_interface_with_min_strain_zsl.ipynb notebook. This notebook will help us create the initial interface structure.

1.4. Set up interface parameters.¶

Edit the notebook parameters to create the Gr/Ni(111) interface:

# Material selection

FILM_INDEX = 1 # Index in the list of materials, to access as materials[FILM_INDEX]

FILM_MILLER_INDICES = (0, 0, 1)

FILM_THICKNESS = 1 # in atomic layers

FILM_TERMINATION_FORMULA = None # if None, the first termination will be used

FILM_VACUUM = 0.0 # in angstroms

FILM_XY_SUPERCELL_MATRIX = [[1, 0], [0, 1]]

FILM_USE_ORTHOGONAL_C = True

SUBSTRATE_INDEX = 0

SUBSTRATE_MILLER_INDICES = (1, 1, 1)

SUBSTRATE_THICKNESS = 4 # in atomic layers

SUBSTRATE_TERMINATION_FORMULA = None # if None, the first termination will be used

SUBSTRATE_VACUUM = 0.0 # in angstroms

SUBSTRATE_XY_SUPERCELL_MATRIX = [[1, 0], [0, 1]]

SUBSTRATE_USE_ORTHOGONAL_C = True

INTERFACE_DISTANCE = 2.58 # Gap between substrate and film, in Angstrom

INTERFACE_VACUUM = 20.0 # Vacuum over film, in Angstrom

# Whether to convert materials to conventional cells before creating slabs.

# To create interfaces with smaller cells, set this flag to False. (and pass already conventional cells as input)

USE_CONVENTIONAL_CELL = True

# Maximum area for the superlattice search algorithm (the final interface area will be smaller)

MAX_AREA = 50 # in Angstrom^2

# Additional fine-tuning parameters (increase values to get more strained matches):

MAX_AREA_TOLERANCE = 0.09 # in Angstrom^2

MAX_LENGTH_TOLERANCE = 0.05

MAX_ANGLE_TOLERANCE = 0.02

# Whether to reduce the resulting interface cell to the primitive cell after the interface creation.

# If the reduction causes unexpected results, try increasing the `MAX_AREA` for search.

REDUCE_RESULT_CELL_TO_PRIMITIVE = True

1.5. Run interface creation.¶

Run the notebook using "Run > Run All Cells". This will:

- Create slabs from both materials

- Find the optimal lattice matching using the ZSL algorithm

- Generate the initial interface structure

2. Optimize Film Position.¶

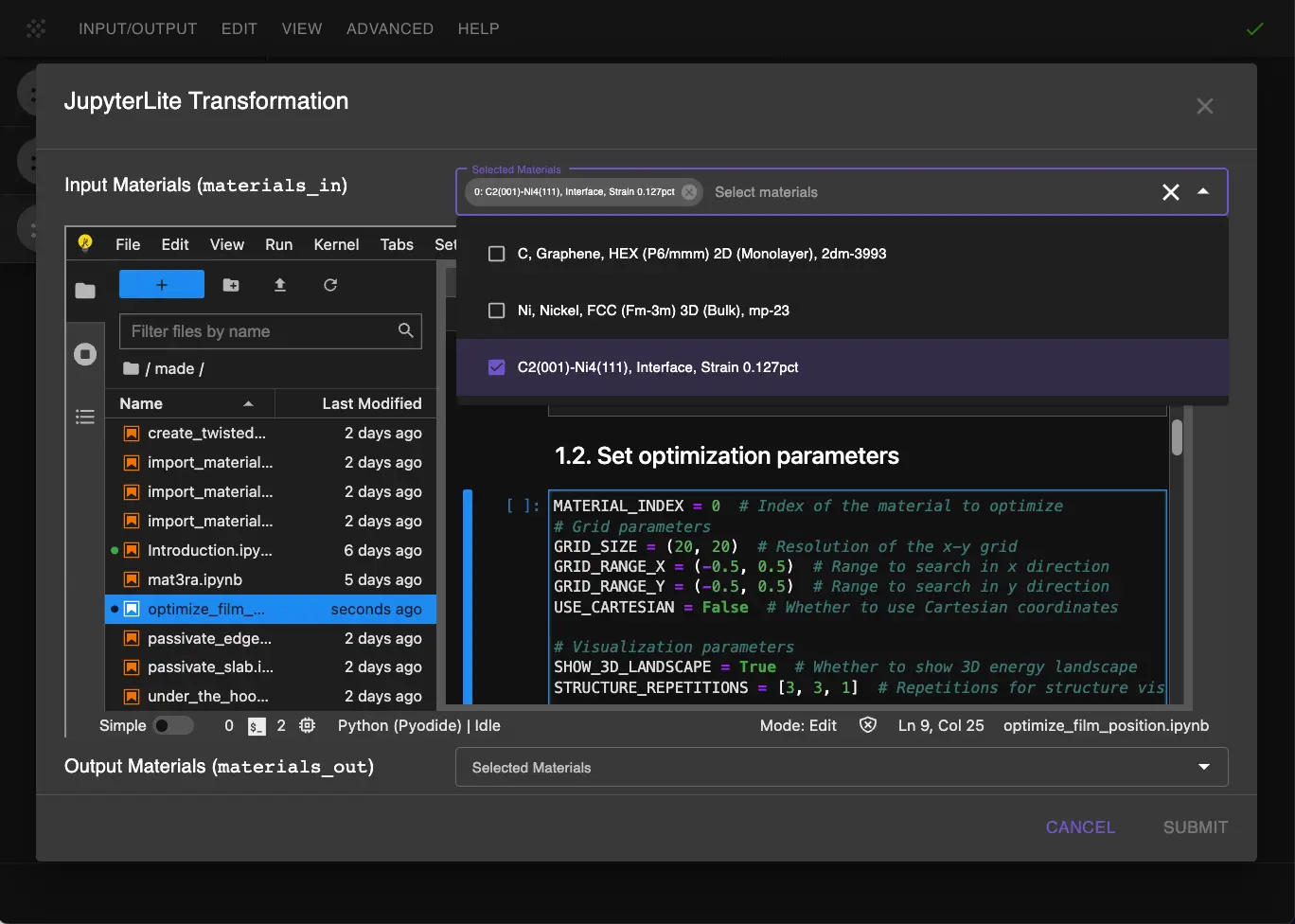

2.1. Open optimize_film_position.ipynb notebook.¶

Find and open the optimize_film_position.ipynb notebook which will help us find the optimal position of the graphene layer.

2.2. Set optimization parameters.¶

Configure the optimization parameters:

MATERIAL_INDEX = 0 # Index of the material to optimize

# Grid parameters

GRID_SIZE = (20, 20) # Resolution of the x-y grid

GRID_RANGE_X = (-0.5, 0.5) # Range to search in x direction

GRID_RANGE_Y = (-0.5, 0.5) # Range to search in y direction

USE_CARTESIAN = False # Whether to use Cartesian coordinates

# Visualization parameters

SHOW_3D_LANDSCAPE = False # Whether to show 3D energy landscape

STRUCTURE_REPETITIONS = [3, 3, 1] # Repetitions for structure visualization

Key parameters explained:

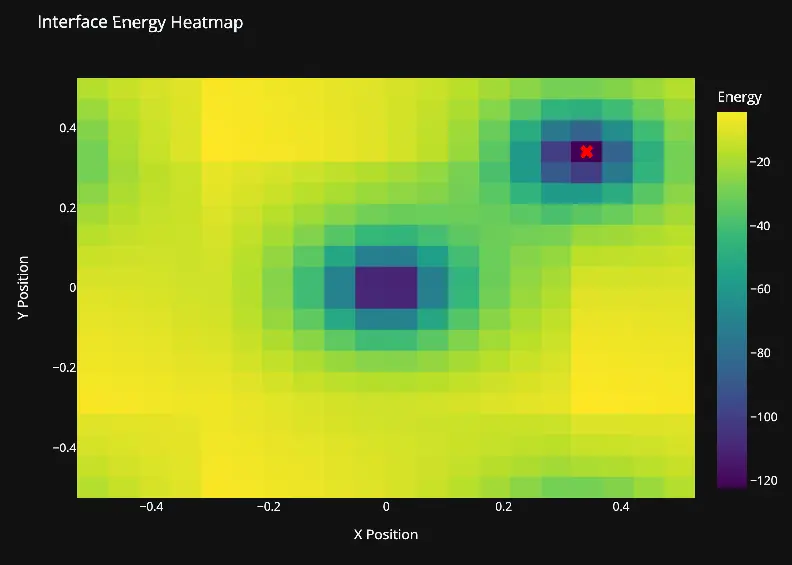

- GRID_SIZE: Controls the resolution of position sampling

- GRID_RANGE: Search range in crystal coordinates

- USE_CARTESIAN: Set to False for hexagonal systems

2.3. Run optimization.¶

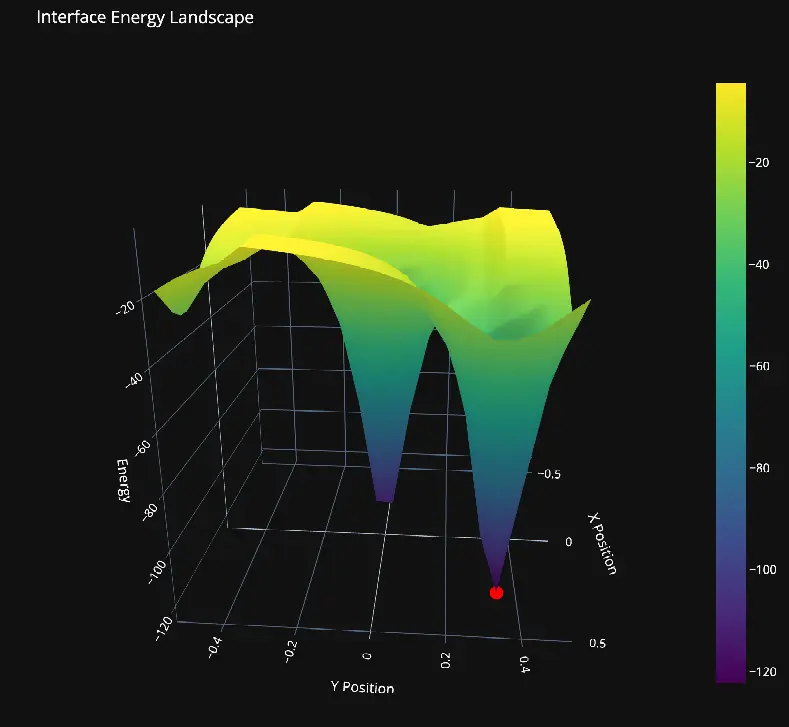

Run all cells in the notebook. The optimization will:

- Calculate energy landscape across different positions

- Find the global minimum energy position

- Generate visualizations of the results

3. Analyze Results.¶

Compare the original and optimized interface structures to see the difference in the graphene position.

4. Save Optimized Structure.¶

The optimized interface structure will be automatically passed back to Materials Designer where you can: 1. Save it in the workspace 2. Export it in various formats (JSON, POSCAR, etc.) 3. Use it for further calculations

Interactive JupyterLite Notebook.¶

The following JupyterLite notebook demonstrates the complete process. Select "Run" > "Run All Cells".

Parameter Fine-tuning.¶

To adjust the interface optimization:

- Interface Creation:

- Adjust

SUBSTRATE_THICKNESSfor more Ni layers - Modify

MAX_AREAto control supercell size -

Change

INTERFACE_DISTANCEif needed -

Position Optimization:

- Increase

GRID_SIZEfor finer sampling - Adjust

GRID_RANGEto search different areas - Enable 3D visualization with

SHOW_3D_LANDSCAPE = True

References.¶

-

Arjun Dahal and Matthias Batzill. Graphene–nickel interfaces: a review. Nanoscale, 6:2548–2562, 2014. URL: https://doi.org/10.1039/C3NR05279F. ↩

-

Y. Gamo, A. Nagashima, M. Wakabayashi, M. Terai, and C. Oshima. Atomic structure of monolayer graphite formed on ni(111). Surface Science, 374(1-3):61–64, 1997. URL: https://www.sciencedirect.com/science/article/abs/pii/S0039602896007856. ↩

-

G. Bertoni, L. Calmels, A. Altibelli, and V. Serin. First-principles calculation of the electronic structure and eels spectra at the graphene/ni(111) interface. Physical Review B, 2004. URL: https://journals.aps.org/prb/abstract/10.1103/PhysRevB.71.075402. ↩